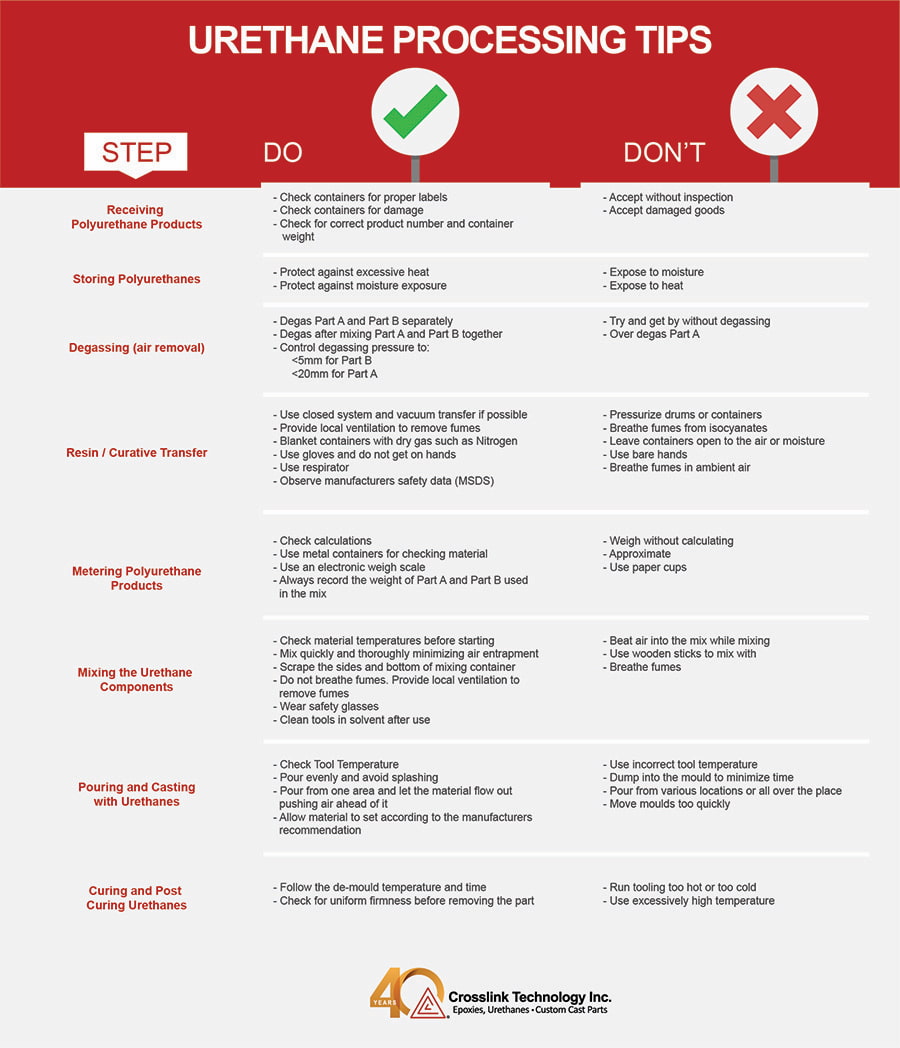

Processing polyurethane compounds are easily achieved following a few basic precautions.

- From the safety stand-point, the major issues are: preventing skin contact and not breathing the fumes while using the compounds.

- From the processing standpoint, it is important to keep moisture from contaminating the resin or hardener and strictly observing the recommended processing and mould temperatures.

Vacuum is highly recommended to remove any air introduced during mixing, watch our video on How to avoid undesirable bubbles. Accurate scales must be used to achieve the correct mix ratio and steel utensils and containers are recommended.

The following represents the basic minimum steps to process urethane products. It may be used as quick reference. When using polyurethane products, consult the Safety Data Sheets or Contact Us for more information on processing our products before engaging in production.

The following instructions are very basic and, if there is any doubt, the user should contact the manufacturer of the urethane compound for detailed instructions before proceeding with full confidence.